Choosing the Right Active Barrier for High Security Infrastructure at Critical Access Points

Protecting critical infrastructure from unauthorized vehicle access requires more than conventional gates, it demands responsive, high-strength solutions. Active vehicle barriers are engineered to stop moving threats in real time, offering integrated crash protection for sites like military bases, government buildings, and energy facilities. Unlike passive defenses, these systems deploy instantly and can be customized with technologies such as license plate recognition, RFID, and emergency override protocols.

Selecting the right system involves more than comparing specs; it requires a full assessment of your site’s risk level, traffic flow, environmental conditions, and certification needs. This guide outlines the key considerations, from technical performance to real-world use cases, to help you identify the most suitable crash rated vehicle barrier. Whether you’re upgrading a checkpoint or securing a high-risk perimeter, understanding your options ensures both compliance and confidence.

Understanding Active Barriers: What They Are and Why They Matter

Active barriers are engineered security devices designed to physically stop, delay, or deny vehicle access through controlled entry points. Unlike passive structures such as fences or static bollards, these systems operate with mechanical or hydraulic force, enabling them to rise, lower, or extend as needed in real time. The primary goal is to prevent unauthorized vehicles from breaching sensitive areas, whether accidentally or with malicious intent.

There are multiple categories of active vehicle barriers, including wedge barriers, retractable bollards, and drop arm barriers. Each system serves a specific purpose, based on threat level, site design, and daily vehicle throughput. For example, a crash rated vehicle barrier installed at a data center may prioritize rapid deployment and seamless access integration, while one at a military checkpoint might emphasize maximum stopping power.

Certification is a key feature that sets these systems apart. Standards such as ASTM F2656 or the now-retired DOS K-ratings test how well a barrier withstands high-speed vehicular impact. An anti crash vehicle barrier with an M50 rating, for instance, can stop a 15,000-pound truck moving at 50 mph. This level of resistance is essential for critical infrastructure facilities where the risk of ramming attacks is high.

Beyond physical strength, active barriers also serve as visual deterrents. Their presence alone can prevent an attempted breach, making them an integral part of layered security strategies. In addition, modern designs often include sensors, cameras, and real-time system diagnostics to enhance situational awareness. Put simply, active barriers are more than just metal and mechanics, they’re proactive security assets designed to protect lives, assets, and operational continuity in high-risk environments.

Key Factors in Selecting an Active Barrier for Critical Access Points

Choosing an active vehicle barrier is a high-stakes decision that hinges on matching performance to your site’s threat level and layout. From stopping power to system reliability, multiple variables must align to ensure effective vehicle control. The following criteria will help guide your selection and ensure the barrier you install meets both operational demands and security expectations.

- Crash Rating Certification: Ensure the system meets ASTM or equivalent global standards (e.g., M30, M50). Higher ratings mean stronger impact resistance.

- Deployment Speed: Time to raise or lower the barrier should align with threat levels. Faster systems are vital in high-risk zones.

- Barrier Type and Function: Choose between wedge barriers, bollards, or drop arms based on site layout, frequency of use, and available space.

- Integration Capabilities: Confirm the barrier can integrate with access control systems, RFID, license plate recognition (LPR), biometrics, for automated, intelligent operation.

- Power Source and Redundancy: Evaluate whether hydraulic, pneumatic, or electric operation suits your site. Backup power (battery or manual override) is critical for reliability.

- Environmental Durability: Look for weatherproof designs, sealed electronics, corrosion-resistant materials, and drainage systems, for consistent performance.

By weighing each of these factors, you can ensure the active vehicle barriers you install are not just functional, but also resilient, compliant, and intelligently integrated with your facility’s broader security infrastructure.

Comparing the Most Common Active Barrier Systems

Choosing the right active vehicle barrier begins with understanding the performance and limitations of the three most common systems: wedge barriers, retractable bollards, and drop arm barriers. Wedge barriers are widely used in high-risk environments such as military bases, government checkpoints, and data centers. They offer exceptional stopping power, with crash ratings like ASTM M30–M50 or DOS K8–K12. These systems deploy in as little as 1–3 seconds and are often integrated with:

- RFID and biometric authentication

- License plate recognition (LPR)

- Emergency lockdown or override controls. However, wedge barriers require significant excavation and are best suited for permanent, high-security installations.

Retractable bollards serve as a discreet yet powerful alternative, especially in urban or mixed-use areas where aesthetics and pedestrian access are key considerations. Commonly installed at embassies, corporate campuses, and public plazas, these bollards carry ASTM M30–M50 crash ratings and typically deploy within three to five seconds. Their minimal surface footprint makes them ideal for locations with limited space or foundation constraints. These barriers can be configured to support scheduled access automation, include manual override mechanisms for emergency control, and maintain low-profile visibility that complements public surroundings. As a result, they provide reliable crash resistance without the extensive excavation or structural demands required by wedge barrier systems.

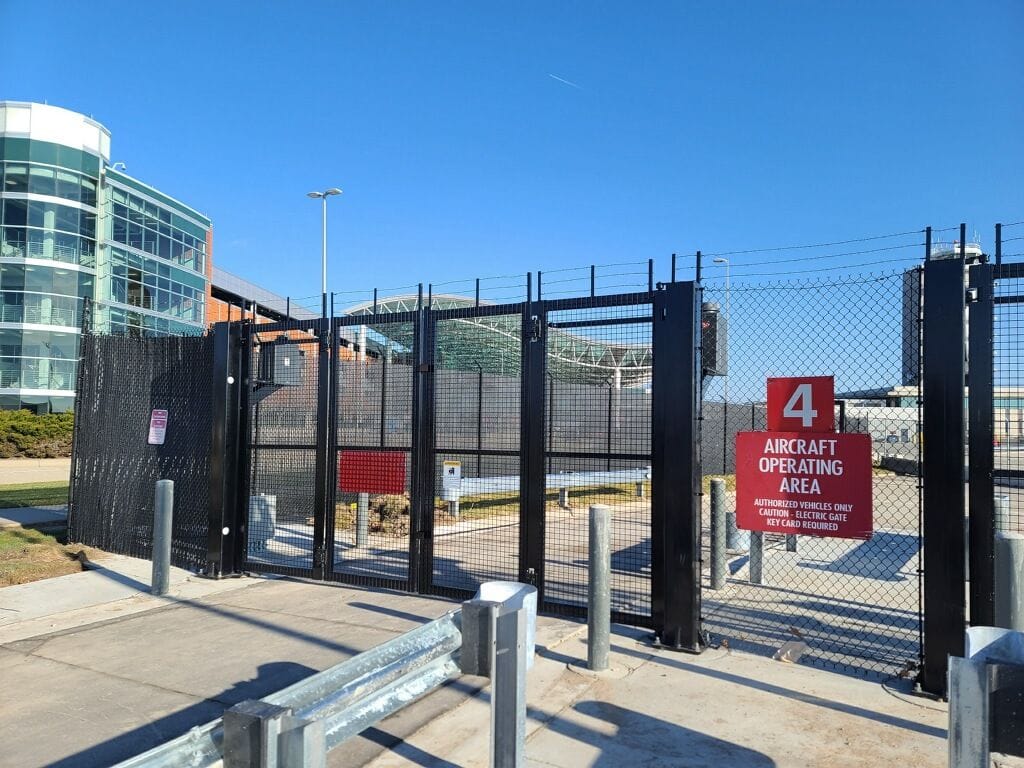

Drop arm barriers offer a visible, fast-acting solution for wide-lane control points like airports, industrial facilities, and correctional centers. With typical ratings of ASTM M30 or DOS K4–K8, these barriers deploy in 2–4 seconds and are usually surface-mounted. Their integration flexibility includes:

- Remote operation via security control rooms

- Surveillance-activated triggers

- License plate scanning for automated entry.

While they may not match the brute strength of wedge systems, drop arms deliver excellent deterrence and are easier to maintain. Choosing among these crash rated vehicle barriers should come down to your site’s threat level, available infrastructure, and daily operational flow.

Site Assessment and Customization for Optimal Security

Before installing any anti crash vehicle barrier, you must first understand the unique risks and operational realities of your site. A thorough site assessment ensures that you’re not just installing a product, but implementing a solution. Follow these six critical steps to customize your barrier system for optimal performance and protection.

- Define the Threat Environment: Determine what you’re protecting against. Is it accidental intrusions, high-speed ramming attacks, or sabotage? High-risk facilities like embassies or research labs require crash rated vehicle barriers with higher impact thresholds (e.g., M50), while commercial campuses may prioritize moderate resistance with high cycle counts.

- Identify Critical Access Points: Map out all vehicle entry and exit routes. Focus on bottlenecks, blind corners, and proximity to high-value assets. Consider foot traffic nearby, some barriers, like bollards, provide a safer mix of pedestrian and vehicular control.

- Evaluate Traffic Patterns and Volume: How many vehicles pass through daily? Are there delivery trucks, emergency vehicles, or peak hours to consider? This data informs your selection of active vehicle barriers with appropriate deployment speeds and duty cycles.

- Examine Infrastructure Limitations: Check the site for underground utilities, drainage systems, or limited excavation zones. For example, wedge barriers may be unsuitable where deep foundation work is restricted, making surface-mounted drop arms a more practical option.

- Customize Operational Requirements: Decide on features such as integration with surveillance systems, badge readers, or remote override capability. Modern anti crash vehicle barrier systems can be programmed for automatic open/close cycles, emergency lockdowns, and fail-safe behavior during power loss.

- Validate with Simulations or Pilot Tests: Before full deployment, simulate barrier performance under real-world conditions. Use traffic modeling software or pilot installations to refine barrier placement, response time, and sensor calibration.

By working through these steps, you transform a generic hardware purchase into a tailor-fit solution that anticipates your facility’s unique threats. Proper planning ensures that your crash rated vehicle barriers don’t just meet specifications, they deliver real, field-proven security.

Regulatory Compliance and Long-Term Maintenance Considerations

When implementing active vehicle barriers at critical access points, compliance and maintenance aren’t optional, they’re central to your system’s legality, reliability, and long-term value. Below are the most common questions security managers ask when navigating certification and upkeep of crash rated vehicle barriers.

Q1: What certifications should I look for in an anti crash vehicle barrier?

Look for ASTM F2656 crash ratings (M30, M40, M50). These standards measure a barrier’s ability to stop a truck of specific weight at a given speed. For example, an M50-rated barrier can halt a 15,000-lb truck at 50 mph. If you’re working on a federal or defense project, these ratings are often mandatory.

Q2: Are crash ratings the same as K-ratings?

No, though they’re related. K-ratings (K4, K8, K12) were developed by the U.S. Department of State and are now largely replaced by ASTM’s M-ratings. Many systems still reference both, so a K8 and M40 system may refer to the same impact performance under different testing standards.

Q3: How often should I perform maintenance on my barrier system?

Monthly functional tests, quarterly inspections, and annual structural reviews are standard. For hydraulic anti crash vehicle barriers, check for fluid leaks and wear on actuators. Electrical systems should be monitored for sensor faults and power irregularities. Preventive maintenance ensures uptime when it matters most.

Q4: What happens during a power outage or cyberattack?

High-quality active vehicle barriers include manual override functions and battery backups to remain operable during emergencies. These fail-safe mechanisms are critical for sites that require uninterrupted perimeter control.

Q5: Who enforces compliance on barrier systems?

Compliance is often enforced at the project level by engineering consultants, government agencies, or insurance carriers. Sites like embassies, airports, or defense facilities must meet crash certification standards to pass inspection and maintain legal protection.

Q6: Is retrofitting an option for older barrier setups?

Sometimes. However, many crash rated vehicle barriers require reinforced foundations and anchoring that existing infrastructure may not support. A full site evaluation is necessary before upgrading legacy systems.

Addressing these considerations early prevents costly redesigns and ensures your security infrastructure operates smoothly under real-world conditions. Remember: a certified, well-maintained system isn’t just a checkbox, it’s the foundation of operational resilience.

Protect Critical Access Points with Black Security Products Barrier Solutions

Choosing the right active vehicle barrier is just the first step, working with a team that understands real-world threats and system performance makes all the difference. At Black Security Products (BSP), we deliver crash rated vehicle barriers engineered to stop unauthorized vehicles on impact, while integrating with modern control technologies to fit your site’s operational needs.

Whether you’re managing access at a military installation, energy facility, government building, or commercial compound, our anti crash vehicle barrier solutions, ranging from wedge barriers to retractable bollards and drop arms, are built for rapid response and long-term reliability. Every system is tested to ASTM standards and tailored to handle specific risk levels, site conditions, and compliance requirements.

Need expert insight before your next perimeter upgrade? Contact us for a consultation, site assessment, or quote on crash-rated systems. Trust our experience, engineering, and commitment to help you stay ahead of evolving vehicle-borne threats.